In this article my goal is to help you keep your pumps running well to minimizing downtime. That means more money in your pocket.

I have traveled all over North America and am always surprised at how many pumps I have come across that don’t run properly. These pumps are costly and when they don’t work there is a direct impact on productivity.

In this article my goal is to help you keep your pumps running well to minimizing downtime. That means more money in your pocket.

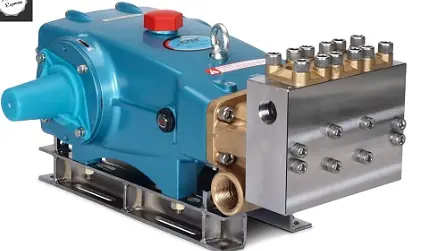

Below you will see that I focus on two of the most popular pumps used in the Hydrovac industry. 1. Cat pumps and 2. Prattazzoli pumps. I have also added some Terry’s tips. I hope this information helps minimize your downtime.

PREVENTIVE MAINTENANCE

For pump reliability and efficiency, comply with maintenance intervals to the manufacture’s specs.

Every day

Check oil level

Clean inline water supply filters

Every 500 hours

Check oil level

Check Valves

Check valve seats

Check springs

Check Valve guides

Check H.P. seals

Check L.P. seals

Every 1000 hours

Change oil

Check or Replace: Valves, Valve seats, Valve springs, Valve guides, H.P. seals, L.P. seals

Troubleshooting the most common problems

Pump pulsates irregularly:

Air suction

Insufficient supply

Bends, elbows, fittings on the suction line are choking the passage of liquid

Suction filter is dirty or too small

The booster pump, if installed, is supplying insufficient pressure or flow rate

The pump is not primed due to insufficient head or the outlet is closed during priming

The pump is not primed due to valve jamming

Worn valves

Worn pressure seals

Faulty pressure control valve

Problems with the transmission

Pump does not make any noise upon start-up:

The pump is not primed and is running dry

No suction water

Valves are jammed

The outlet line is closed and does not allow the release of air present in the pump manifold

Pump pulsates irregularly:

Air suction

Insufficient supply

Bends, elbows, fittings on the suction line are choking the passage of liquid

Suction filter is dirty or too small

The booster pump, where installed, is supplying insufficient pressure or flow rate

The pump is not primed due to insufficient head or the outlet is closed during priming

The pump is not primed due to valve jamming

Worn valves

Worn pressure seals

Imperfect functioning of the pressure control valve

Problems on the transmission

Reduced flow or excessive noise:

Insufficient supply (see various causes as above)

Pump speed is below the rated speed

Excessive internal leakage of pressure control valve

Worn valves

Excessive leakage from the pressure seals

Cavitation due to:

Improper sizing of suction ducts/undersized diameters

Insufficient flow rate

High water temperature

Insufficient Pressure:

The user flow (nozzle) is or has become greater than the pump capacity

Abnormal revolutions per minute. – Excessive leakage from the pressure seals

Imperfect functioning of the pressure control valve

Worn valves. Pump overheats:

The pump is working in over pressure conditions or pump rpm is higher than the nominal value

Oil in the pump casing is not at level or not the recommended type

Excess belt tension or joint or pulley alignment is incorrect

Excessive pump tilt during operation

Vibrations or hammering on pipes:

Air suction

Faulty operation of pressure control valve

Valves malfunction

Non-uniformity of transmission motion

PRATISSOLI PUMPS

Oil must be changed at least once a year, as it is degraded by oxidation

For a room temperature other than between 0 °C – 30 °C, follow the instructions, considering that oil must have a minimum viscosity of 180 cSt

The pump is supplied with oil suitable for room temperatures from 0 °C to 30 °C. Recommended types of oil are indicated in the table below, these oils have additives to increase corrosion resistance and fatigue resistance. Alternatively, you can also use Automotive Gear SAE 85W-90 oil for gearing lubrication.

PREVENTIVE MAINTENANCE

Every 500 hours

Check oil level

Every 1000 hours

Change oil

Check / Replace:

Valves

Valve seats

Valve springs

Valve guides

P. seals

P. seals

Brands and types of oils recommended:

AGIP ACER220

Aral Degol BG 220

BP Energol HLP 220

CASTROL HYSPIN VG 220 CASTROL MAGNA 220

Falcon CL220

ELF POLYTELIS 220 REDUCTELF SP 220

NUTO 220 TERESSO 220

FINA CIRKAN 220

RENOLIN 212 RENOLIN DTA 220

Mobil DTE Oil BB

Shell Tellus Öl C 220

Wintershall Ersolon 220

Wintershall Wiolan CN 220

RANDO HD 220

TOTAL Cortis 220

Check the oil level and top off if necessary, using the oil dipstick. The correct checking of the oil level is made with the pump not running, at room temperature. The oil change must be made with the pump at working temperature. The quantity required is ~ 3.8 liters.

CAT PUMPS

Pump and System Preventive Maintenance Guidelines

Many application factors determine proper pump maintenance intervals. Variation in duty cycle, operating performance, fluid temperature, fluid type, inlet conditions and application environment can affect maintenance schedules. Every application should be evaluated and serviced based on its own requirements.

Water leaks or loss of system performance can be an indicator of seal wear. Seal wear has many causes, including contaminated liquid or high-temperature/run dry operation. If the low-pressure seals show wear, the high-pressure seals most likely are in a similar condition. It is a good practice to replace both low and high pressure seals and inspect plungers when leaks are present.

Cat Pumps recommends using our custom-blend premium grade hydraulic oil formulated to meet Cat Pumps specifications. For best results, perform an initial oil change after the first 50 hours of operation and every 500 hours thereafter. If other oil is used, oil change should be performed every 300 hours of operation.

If system performance degrades or changes, check seals and valves immediately. Service as required to restore system performance. Depending upon operating conditions, maintenance intervals for seals kits range between 1,500 and 8,000 hours.

Pump valves typically require changing every other seal change. Depending upon operating conditions, maintenance intervals for valve kits range between 3,000 and 16,000 hours.

Doing simple routine maintenance and paying attention to your equipment is always affordable. Not doing so is costly.